Currently, there are two main types of laminar flow: horizontal flow and vertical flow.

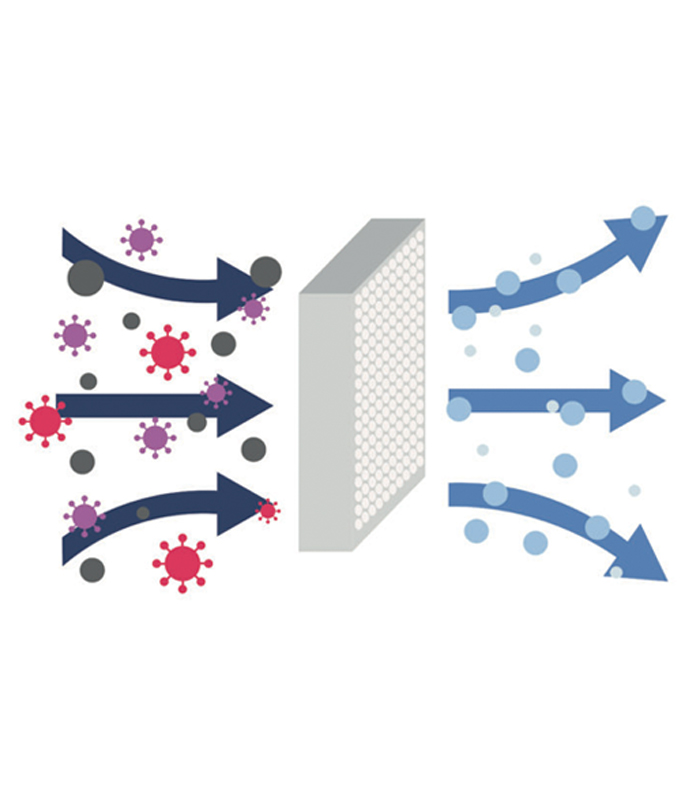

Horizontal unidirectional airflow: Cabinets equipped with horizontal laminar flow allow, for example, the evacuation of particles without turbulence. Air enters the cabinet through a horizontal filtration system and exits through a perforated grille. The airflow thus prevents the accumulation of contaminants generated inside the so-called “clean” area by quickly carrying them towards the return surface.

Vertical unidirectional airflow: Vertical flow allows you to achieve the desired air quality over the surface of your cabinet. In other words, this type of airflow is effective across the entire volume, including its width, height, and depth. However, note that with this model, you won’t be protected from various turbulences. In this case, air is blown from a vertical filtration system and is returned through a vertical plenum equipped with perforated plates. The horizontal flow system is a very convenient system offering the best efficiency/cost ratio.

In summary, you should make your choice based on the positioning and characteristics of your samples. For example, handling a low-thickness product requires a horizontal airflow cabinet. Otherwise, it is better to opt for the other type of cabinet to maximize the evacuation of particles from the point of use.